All Products

It dissolves the structure of the oils found on the surfaces and separates them into inactives.

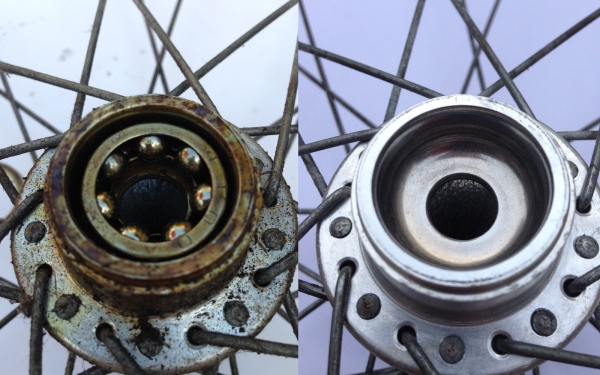

It corrodes the surface microscopically with surface-controlled methods for better adhesion of painting and coating. This feature also allows rust and scale coated surfaces to be cleaned.

It reacts with the surface and converts iron oxide to iron phosphates, thanks to the components in its formula. This new layer prevents the inner rusting of the surface after painting and coating.

One unit ORICLEAN is used by being diluted in 5 to 20 units of water. As it can be used cold, it eliminates the energy consumption resulting from heating and heat preservation.

It is used in preliminaries of brass, copper, lead, bronze, aluminium and stainless materials.

| DILUTION INSTRUCTIONS | |

| HEAVY OIL AND RUSTY METAL CLEANING | IMMERSION: 1/5 ERASURE: 1/15 |

| ALUMINIUM, BRASS, COPPER CLEANING | IMMERSION: 1/10-1/20 ERASURE: 1/20 |

| STAINLESS MATERIAL OIL CLEANING | IMMERSION: 1/8 ERASURE: 1/15 |

In the cases where ORICLEAN will be used by immersing, the immersion tank needs to be made of stainless steel or an insulated DKP sheet.